TDS Intelligent Dry Sortors

.png)

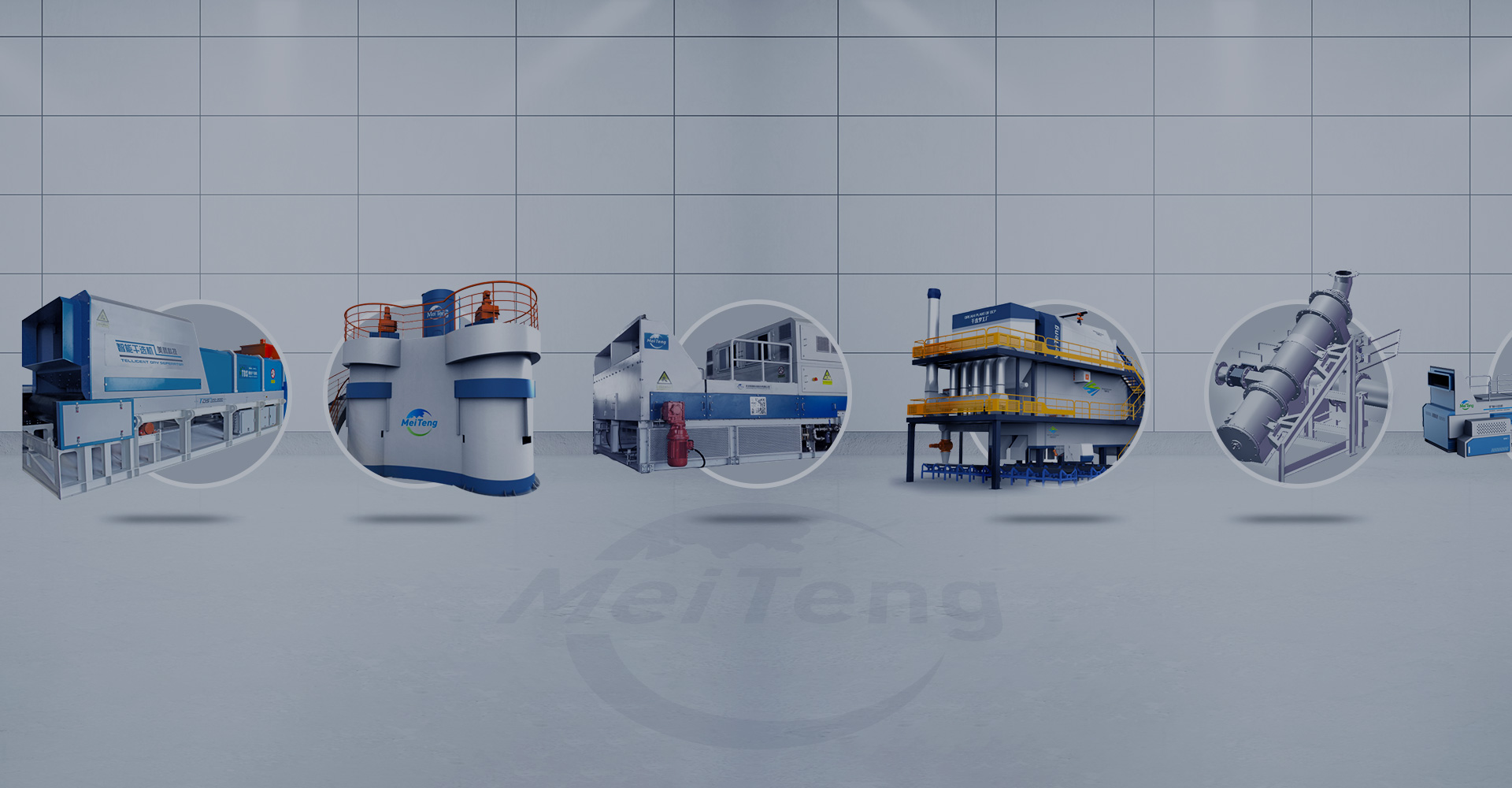

The TDS intelligent dry sortor, an intelligent coal-reject sorting equipment self-developed by Meiteng technology, broke through the limitations of traditional mineral processing technologies. By the end of December, 2022, the accumulated sales amount of TDS has reached 270 sets. The sorting accuracy of TDS exceeds that of water washing (jigging) and the changes brought by TDS to the coal industry is revolutionary. Its outstanding performances and stable operations have resulted in TDS becoming the number one choice in the industry.

By using advanced intelligent recognition technology, TDS can establish corresponding analysis models based on different coal characteristics to perform big data analysis, therefore digitally recognize coal and reject, and separate them with the help of high pressure air blowing controlled by high-speed solenoid valve. TDS`s application in varies regions and coal quality sites have accumulated a large amount of coal quality data for Meiteng, which brought more than 70 types of algorithms model (including material segmentation, classifification and air blowing) to satisfy the high sorting accuracy needs. Our first TDS was put into operation in Zhaozhuang CHPP back in 2016, and it has been stably working until now. Through all these years, Meiteng kept on making innovations regarding TDS, and has achieved multiple major breakthroughs, enriching the functions from pre-concentration to product direct output, from single source recognition to double sources recognition, from two products output to three products output, from fixed type to mobile type, from ground sorting to underground sorting, from coal sorting to minerals sorting, etc.

TDS PRINCIPLE

TDS is an intelligent equipment for separating coal and reject independently developed by Meiteng technology, which is an innovation of mineral processing technology that has not changed for more than 100 years. The separation accuracy of TDS exceeds that of water washing (jigging) and it has operated stably in the mining industry for a long time. TDS adopts intelligent identifification method to establish an analysis model corresponding to different coal quality characteristics. Through big data analysis, the coal and reject are digitally identified, and finally the reject is discharged through the intelligent reject discharge system. TDS consists of several major systems including feeding, identifification and execution, as well as auxiliary systems such as air supply, dust removal, power distribution and control.

.gif)

Meiteng TDS/XRT series products have completed the radiation exemption filing on December 10th, 2021. According to the "Management Measures for the Safety and Protection of Radioisotopes and Radiation Devices" issued by the Ministry of Environmental Protection of the People's Republic of China Order No. 18, they can be exempted from management, and product users can also be exempted from management. The radiation exemption is the lifelong type, with one-time exemption and lifelong exemption.

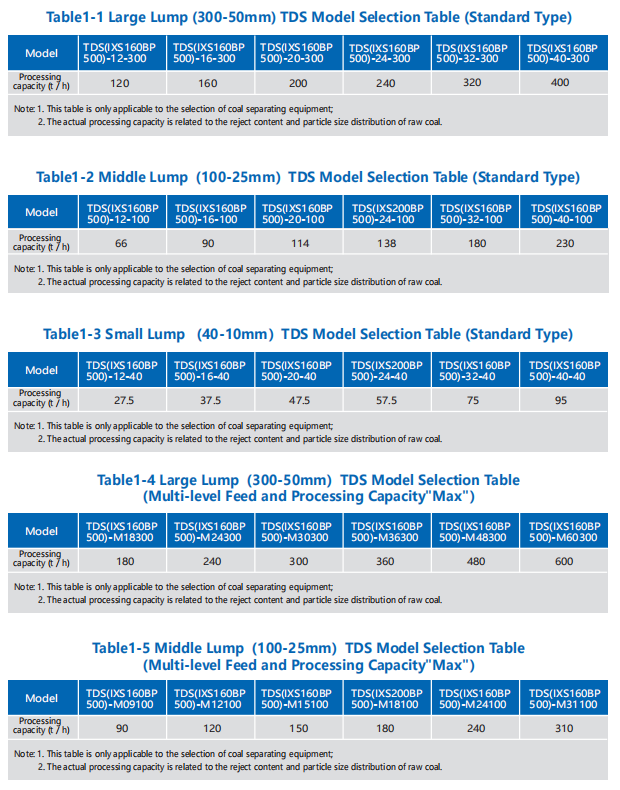

Ground TDS Model Table

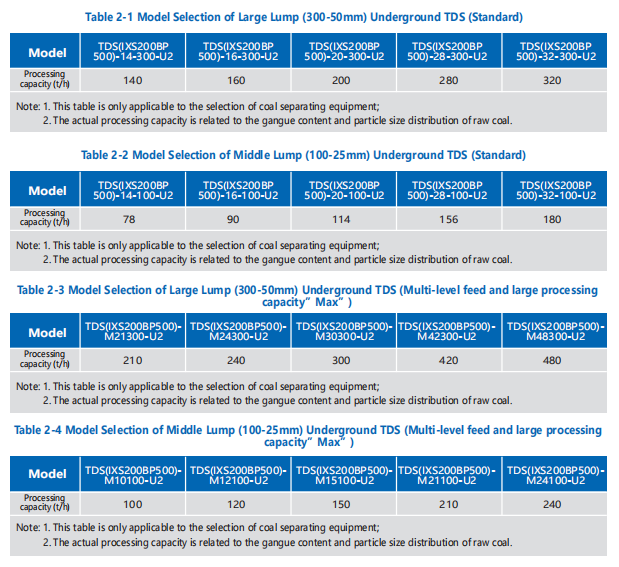

Underground TDS Model Table

Back to Top